School

of mines

The Genesis

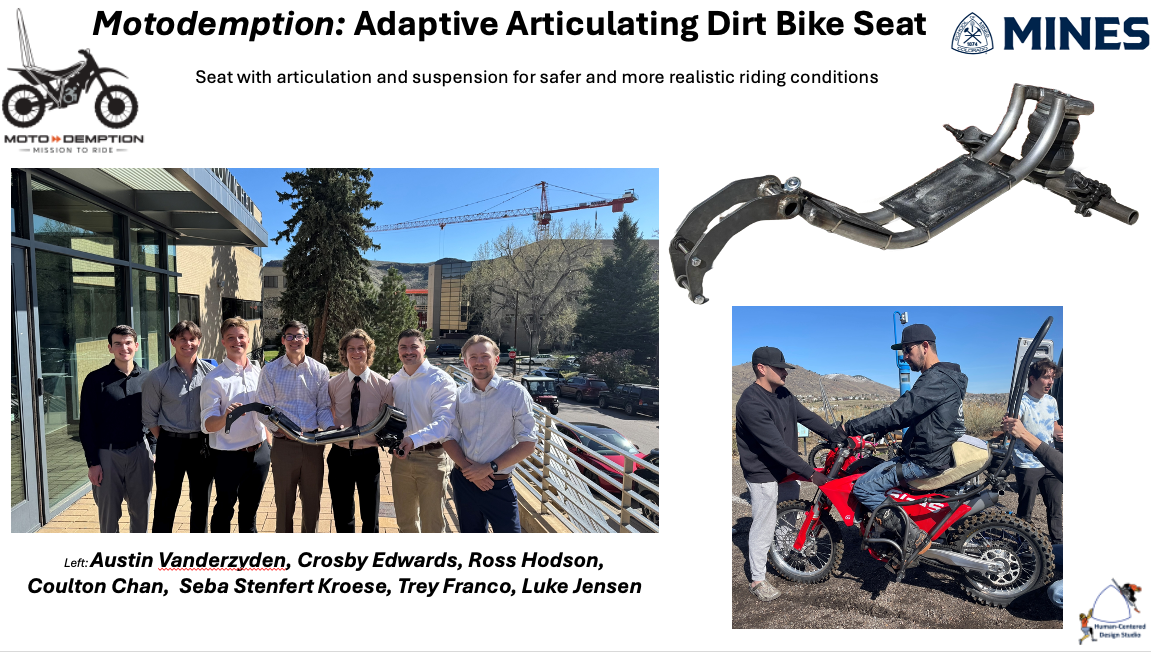

Over the past year, Motodemption has been proud to partner with the engineers, professors, and students of the Colorado School of Mines, one of the most prestigious engineering schools in the world. This partnership represents not only a technical collaboration but also a commitment to innovation, inclusion, and the future of adaptive sports. Together, we are pushing the boundaries of what is possible in adaptive motocross by addressing both safety and performance needs through groundbreaking engineering solutions. The demand for adaptive dirt bikes has never been higher. Motodemption receives applications from individuals with disabilities from all over the world—each one a story of resilience and a desire to ride again despite life-changing injuries. Meeting this demand requires more than simply modifying existing bikes. It requires new designs, advanced engineering, and adaptive systems tailored to the unique needs of riders with spinal cord injuries, amputations, and other mobility challenges. This is where the Colorado School of Mines came in. By embedding our vision into their senior Capstone Project, we launched two key innovation directives: A complete redesign of our adaptive safety cage—the Moto-Shield—with a focus on weight reduction and enhanced rider protection. Development of a new adaptive seat featuring side-to-side articulation and integrated suspension to better support riders with limited mobility and spinal cord injuries. Both initiatives were carried out in structured phases, blending classroom learning, advanced simulations, hands-on fabrication, and most importantly, rider input. The result has been transformative—not only for the technology but for the confidence, safety, and performance of adaptive riders everywhere. Over the past year, Motodemption has been proud to partner with the engineers, professors, and students of the Colorado School of Mines, one of the most prestigious engineering schools in the world. This partnership represents not only a technical collaboration but also a commitment to innovation, inclusion, and the future of adaptive sports. Together, we are pushing the boundaries of what is possible in adaptive motocross by addressing both safety and performance needs through groundbreaking engineering solutions. The demand for adaptive dirt bikes has never been higher. Motodemption receives applications from individuals with disabilities from all over the world—each one a story of resilience and a desire to ride again despite life-changing injuries. Meeting this demand requires more than simply modifying existing bikes. It requires new designs, advanced engineering, and adaptive systems tailored to the unique needs of riders with spinal cord injuries, amputations, and other mobility challenges. This is where the Colorado School of Mines came in. By embedding our vision into their senior Capstone Project, we launched two key innovation directives: A complete redesign of our adaptive safety cage—the Moto-Shield—with a focus on weight reduction and enhanced rider protection. Development of a new adaptive seat featuring side-to-side articulation and integrated suspension to better support riders with limited mobility and spinal cord injuries. Both initiatives were carried out in structured phases, blending classroom learning, advanced simulations, hands-on fabrication, and most importantly, rider input. The result has been transformative—not only for the technology but for the confidence, safety, and performance of adaptive riders everywhere.

Adaptive Seat

Comfort, Balance, and Control

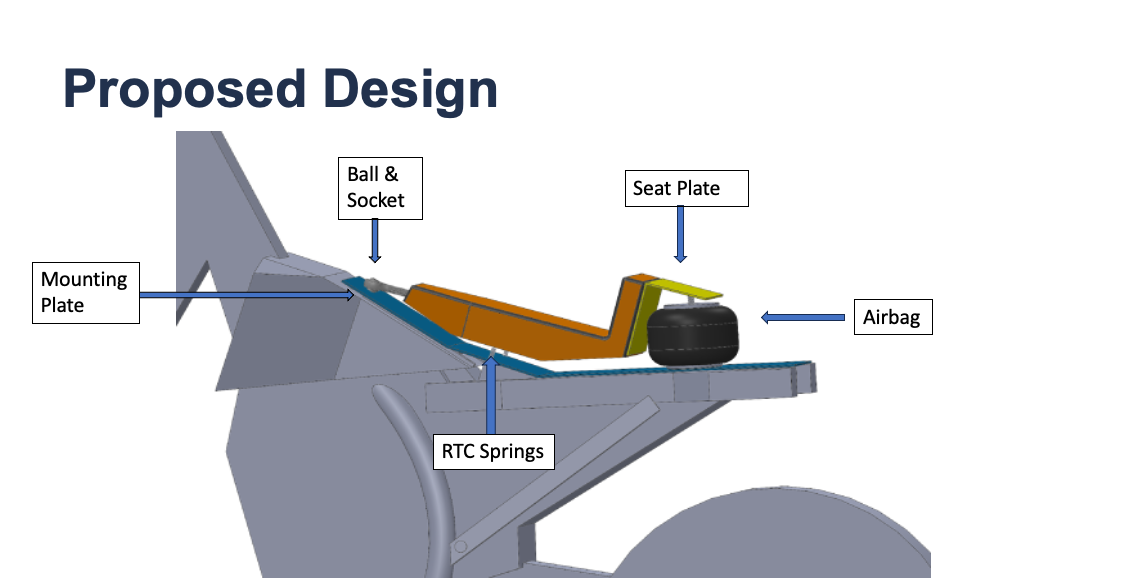

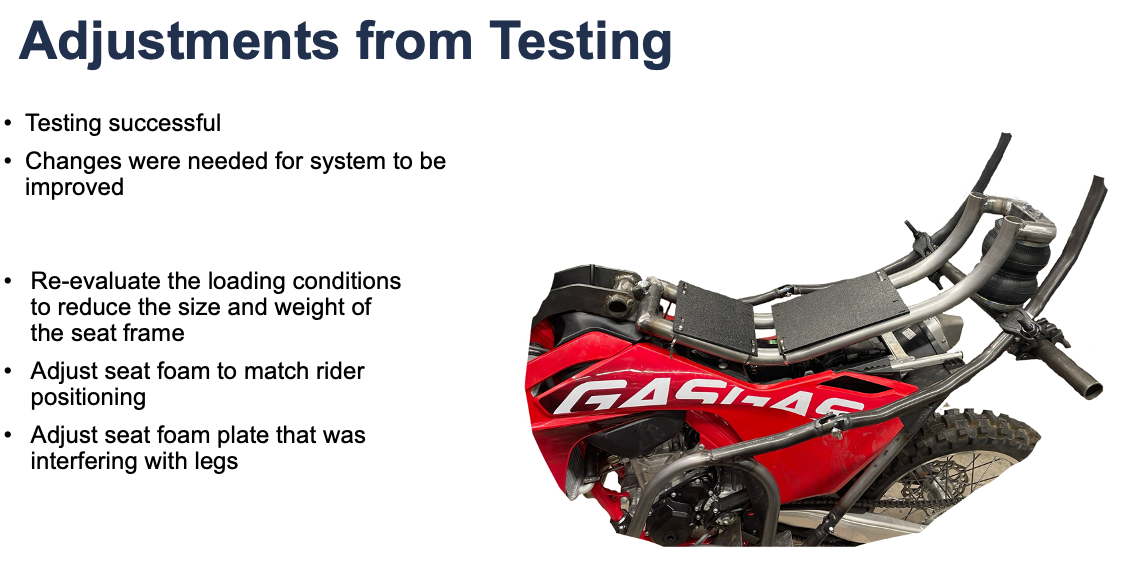

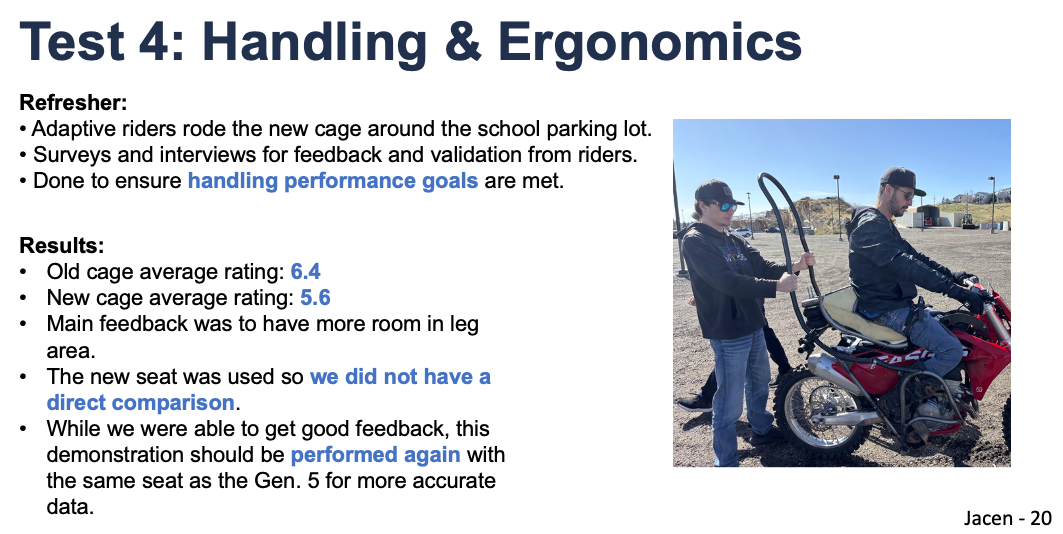

If the Moto-Shield provides external safety, the adaptive seat ensures internal stability, comfort, and control. For riders with spinal cord injuries or limited mobility, a standard motocross seat cannot provide the support or shock absorption required to ride safely. That’s why Mines engineers and Motodemption launched the Adaptive Seat Initiative—a project aimed at redefining how riders connect to their bikes. The process began with ergonomic studies and rider feedback. Adaptive athletes played a crucial role in shaping the design, sharing their experiences, needs, and frustrations with current seat technology. How did the seat affect their ability to balance in corners? Did certain terrains cause excessive impact on the spine? What adjustments could make the difference between discomfort and confidence? These insights formed the foundation of the design. Based on this data, the Mines team engineered a new seat structure featuring side-to-side articulation. This breakthrough allows the rider to counterbalance lean angles during turns and terrain changes—something previously difficult or impossible for many adaptive riders. With this innovation, riders gained greater control, fluidity, and independence on the bike. Material choice was another key factor. The team selected medical-grade materials known for durability, safety, and biomechanical support. These materials ensured that the seat could withstand both the physical demands of motocross and the unique needs of riders with spinal cord injuries. The final stage of development integrated additional suspension elements into the seat base. These elements absorbed impact forces during landings and rough terrain, reducing stress on the rider’s spine and minimizing the risk of secondary injury. The result was not only a safer ride but also a more enjoyable one—allowing riders to focus on the thrill of motocross rather than the discomfort of every bump. The Adaptive Seat Initiative stands as a model of rider-centered engineering, blending cutting-edge design with compassion and respect for the athlete experience.

MotoShield

Redefining Adaptive Safety

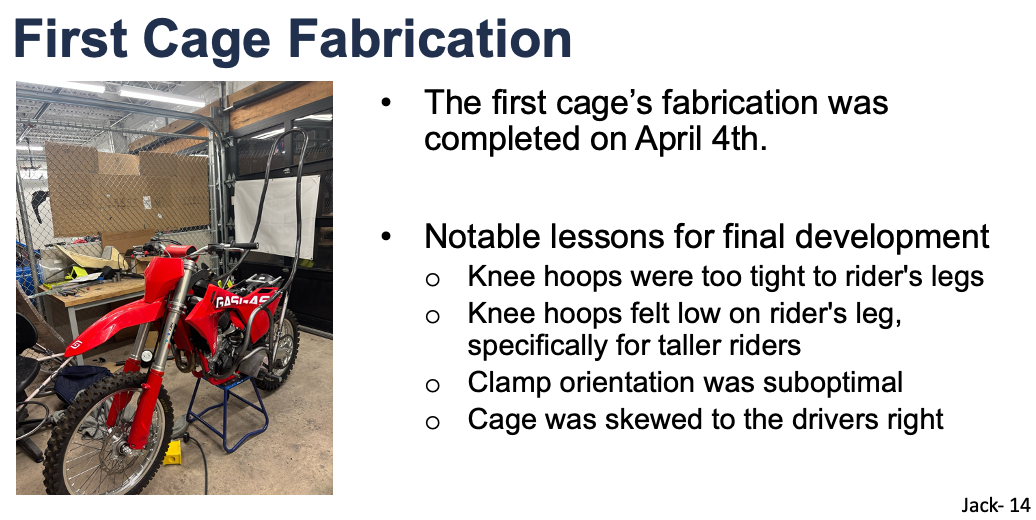

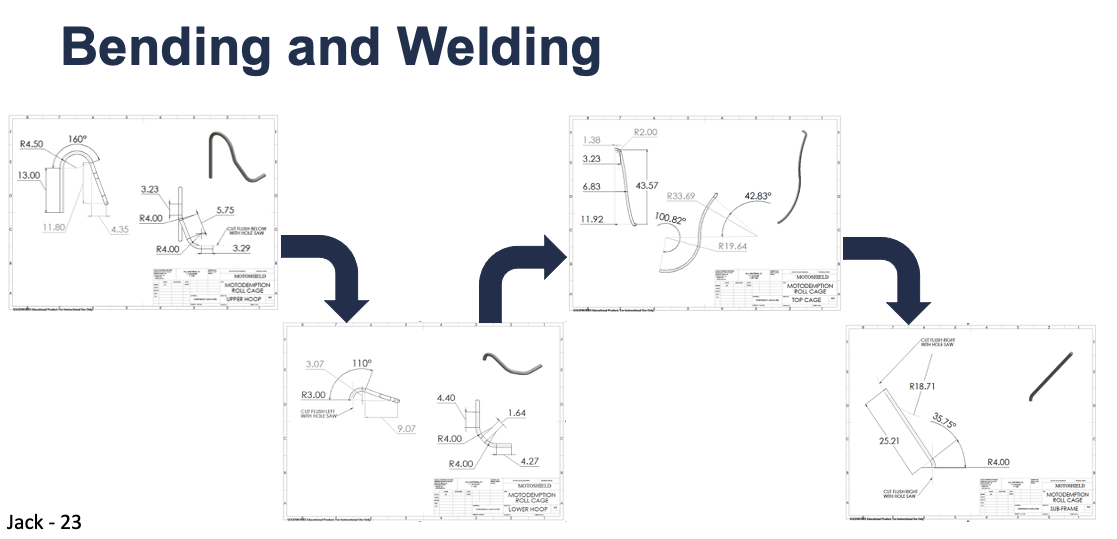

The Moto-Shield has long been a cornerstone of adaptive motocross. It functions as a protective safety cage, helping to stabilize and safeguard riders who may not have full use of their lower limbs or core strength. While effective, the original design left room for improvement in terms of weight, balance, and protection. The Mines team approached this challenge with a disciplined, engineering-first mindset. The project began with a comprehensive design phase, where students created detailed SolidWorks models tailored specifically for adaptive motocross applications. Every angle, joint, and reinforcement was modeled with the rider in mind, ensuring that the final design could withstand the extreme forces encountered on a motocross track. From there, the team ran computer-based simulations to test performance under a range of load scenarios. How would the Moto-Shield hold up during a sharp corner? What forces would it encounter on a rough landing from a jump? Would a lighter material compromise its ability to protect the rider? These questions guided the process, and through iterations of digital testing, the team identified potential weak points and areas for weight optimization. The next step was Finite Element Analysis (FEA)—a rigorous testing method that measures stress distribution, durability, and load capacity. FEA provided invaluable insights into how the Moto-Shield would behave under real-world conditions. It highlighted stress points, revealed opportunities for reinforcement, and confirmed where weight could safely be reduced without compromising structural integrity. The outcome was a redesigned Moto-Shield with a significantly lower center of mass and a notable reduction in overall weight. These improvements translated directly to better rider stability, smoother handling, and enhanced safety on the track. The lighter design also meant easier installation and transport, increasing the accessibility of the system for adaptive riders and their families. Beyond the technical advances, the Moto-Shield project symbolized something deeper: a commitment to continuous improvement. Each phase of the redesign built upon the last, ensuring that the final product was not only safer and more efficient but also adaptable for future iterations as rider needs evolve.

.png)

.png)

.png)